Home > Fachsektionen > Halle > Algae screening

Based on the enormous evolutionary diversity of phototrophic microorganisms and their largely untapped potential to form economically valuable secondary metabolites, the declared aim of the project “Controlled optical sensor-actuator system for the targeted induction of high-value products in photobioreactors” was to to develop a novel controlled photo-optical laboratory cultivation system to address the photosystems of microalgae, cyanobacteria, but also higher organized phototrophic organisms in an energy-efficient and demand-oriented manner. The aim was to create an innovative experimental system for laboratory work with phototrophic microorganisms such as microalgae, cyanobacteria or duckweed with maximum degrees of freedom in relation to the cultivation parameters. In particular, the stress-induced biosynthesis of valuable products such as carotenoids, unsaturated fatty acids or polymeric cell wall components is the focus of interest in current work with the device.

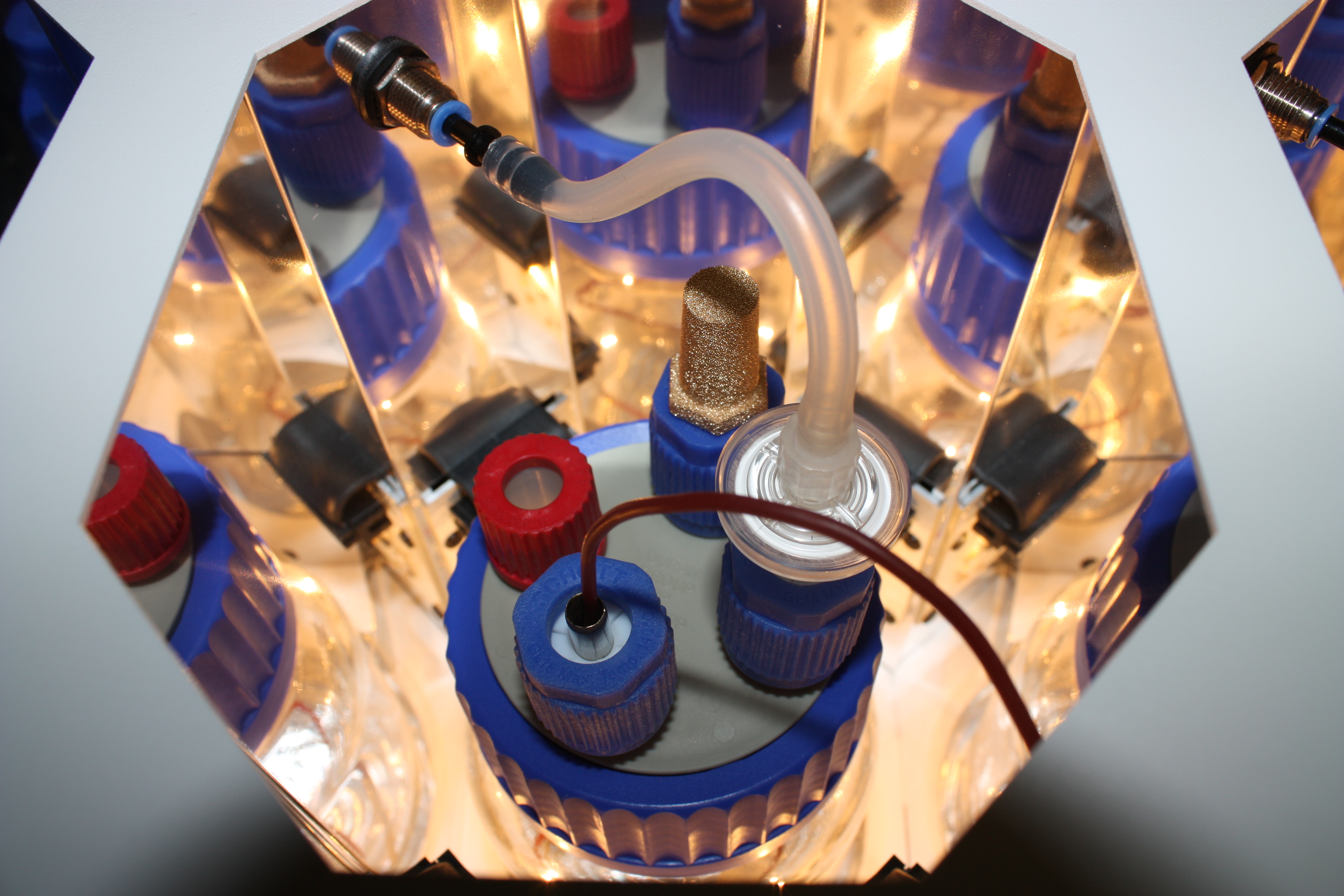

In collaboration with the project partners, the PhytoLux® system was developed, with which extensive and statistically verified experiments can be planned and carried out within a very short time. For this purpose, 16 identically equipped, aseptically controllable measuring stations on a 500 ml scale are used, which can be operated in a defined manner with regard to temperature, lighting and gas supply. Illumination systems have been integrated that represent an absolute novelty in the field of photobioreactor technology in terms of their performance in terms of spectral properties and light intensities. The equipment system is technically sophisticated, yet compact, mobile and designed for everyday laboratory use.

Device features:

Project partners: Ventury GmbH Dresden ; Promed Computertechnik GmbH ; OUT e.V. Berlin

Duration: 01.11.2013 – 31.10.2015

Funding body: AiF Projekt GmbH on behalf of the BMWi

© Gesellschaft zur Förderung von Medizin-, Bio- und Umwelttechnologien e.V.