Home > Fachsektionen > Halle > Functional prototyping

As a part of R&D projects and customer orders different prototypical solutions and product developments up to small series have been realized.

Prototypes and engineered products that were successfully realized thanks to additive processes include:

Additionally, we handle process-related developments like:

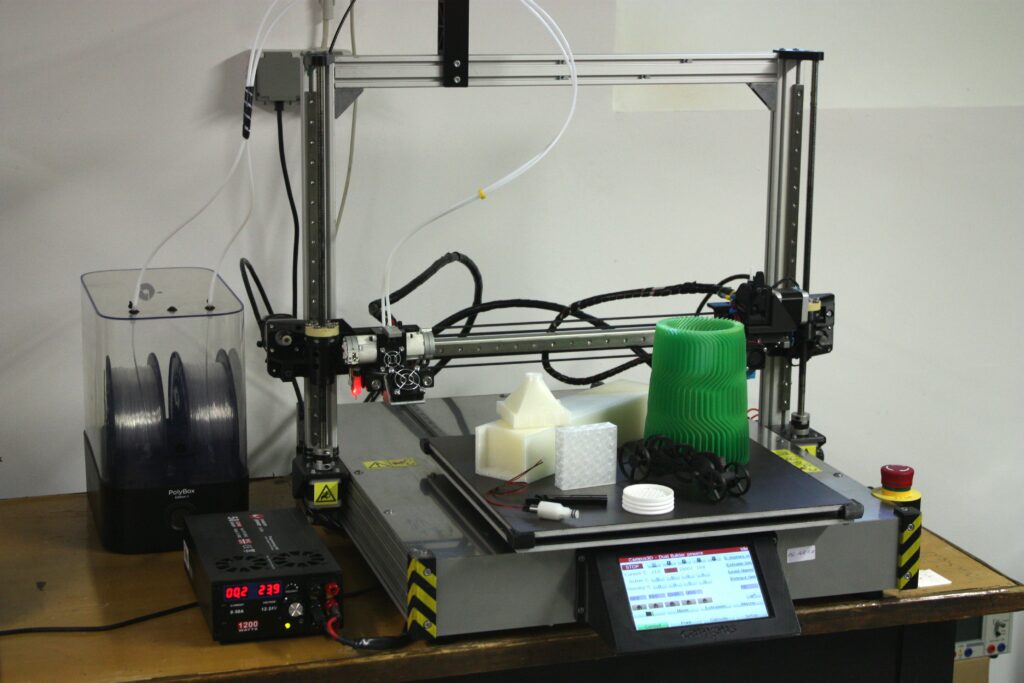

The additive processing was done as Fused Deposition Modeling (Fused Filament Fabrication / Fused Granular Fabrication). On the one hand, the advantage of FDM is the wide range of suitable materials: basically all available thermoplastics can be processed, including extrusion and fused deposition types – although not all materials are equally suited. On the other hand, the market offers a large choice of different machines especially for filament-based processing – from hobby device to industrial-suited machine. Therefore FDM is currently the most widely used method.

© Gesellschaft zur Förderung von Medizin-, Bio- und Umwelttechnologien e.V.